Harmonic reducer oil seal

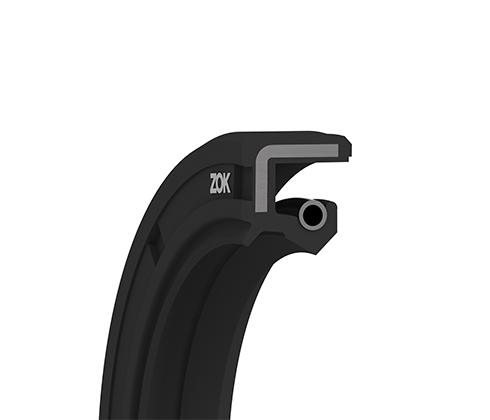

Robot harmonic reducer oil seals are special sealing components tailored for the precision, high-frequency, low-backlash operating conditions of harmonic reducers. Adopting a composite structure of metal framework + FKM/HNBR, the main lip is equipped with a built-in micro-tension spring to closely fit the output shaft of the flexspline or the end face of the circular spline. These seals not only lock internal grease and prevent leakage from contaminating robot joints, but also isolate dust and moisture intrusion. Withstanding a wide temperature range of -30℃~150℃ and high-frequency reciprocating oscillation, they ensure the meshing accuracy and operational stability of the reducer, and extend the maintenance interval of robot joints.

功能特点

01Dual Seal Protection Leakage Prevention: The main lip is equipped with a self-tightening spring to lock in internal grease (e.g., lithium-based grease), reducing the risk of leakage-related faults by over 30% and ensuring transmission accuracy. Contamination Prevention: Double-lip/multi-lip structure + dust lip blocks dust, cutting fluid and moisture, protects precision components such as flexsplines, and is suitable for severe operating scenarios including welding and spraying.

Low Friction & Adaptability Low-Torque Design: Optimized lip curvature and surface treatment ensure dynamic friction coefficient fluctuation ≤ ±3%, reducing energy consumption and meeting the low-power requirements of collaborative robots. Oscillation Followability: The elastic lip structure compensates for deflection, adapts to high-frequency start-stop and reciprocating oscillation conditions of harmonic reducers, and prevents lip uneven wear.

Resistance to Severe Conditions & Long Service Life Weather-Resistant Materials: Mainstream FKM sealing lips withstand temperatures ranging from -20℃ to 200℃, featuring excellent anti-aging and oil-resistant performance. VMQ (for food/medical applications) or PTFE (for ultra-low temperature/chemical corrosion scenarios) options are available. Reliable Structure: Thin steel plate/stainless steel framework ensures structural rigidity; self-tightening springs continuously compensate for wear, delivering a service life of ≥ 8000 hours under normal operating conditions.

Compact Installation Small Cross-Section Design: Tailored for the narrow cavities of harmonic reducers; the external thread facilitates installation and compensates for cavity ovality.

Product Superiority

02Transmission Accuracy Assurance: Reliable sealing prevents gear/bearing wear caused by grease leakage, maintaining the high precision of harmonic drive (repeat positioning accuracy ≤ ±0.01mm).

Service Life & Maintenance Optimization: Long-service-life design combined with easy-installation structure extends maintenance intervals and reduces downtime and replacement costs.

Energy Consumption & Adaptability Upgrade: Low-torque and lightweight features cut down joint drive energy consumption, ideal for the compact design of humanoid/collaborative robots.

Customized Adaptability: Lip structure, material and spring configuration can be customized according to shaft diameter (15–100mm) and operating conditions (temperature/medium).

-

Functional Characteristics

-

Product Superiority

-

Product Paramete

Solving your equipment sealing challenges

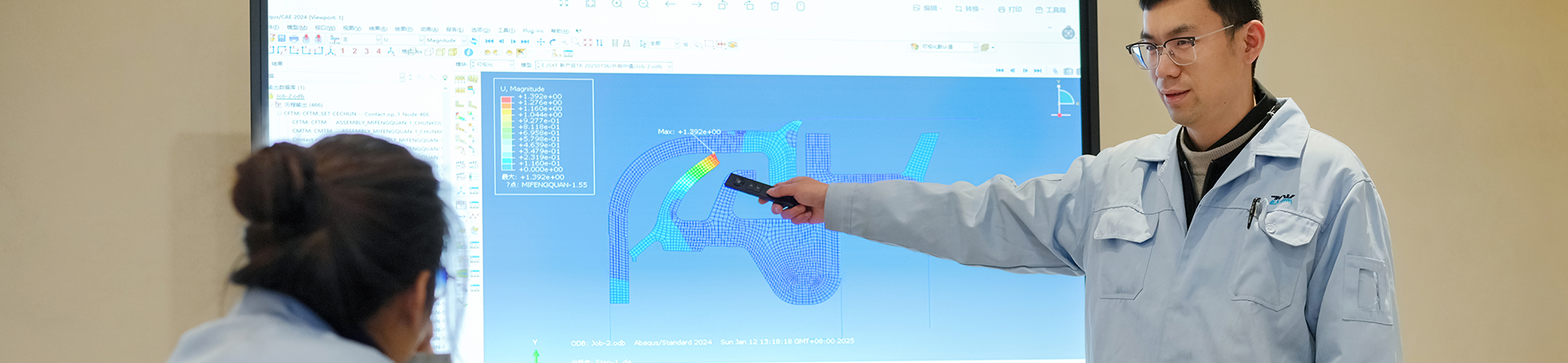

Contact us, and we shall promptly provide you with customized oil seal solutions through our expertise and capabilities.

Contact Us

Major Content:

Submit the form to obtain the document

We will contact you and send you the document