Robot

Product Applications

Precise mapping of motion states

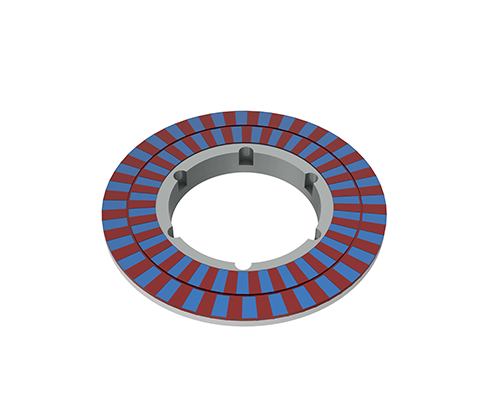

The magnetic encoder, a magnetic field generator with pre-programmed magnetic pole distribution (a "magnetic field code book"), produces regular magnetic field variations matching joint rotation displacement. Magnetic sensors (e.g., Hall effect devices) capture these changes and convert physical motion into quantifiable electrical signals. Its non-contact design avoids friction-induced accuracy loss, ideal for joints with frequent start-stop movements.

The Perceptual Foundation of Control Systems

Encoder output signals are processed into digital commands for position, angle, or velocity. Absolute encoders directly provide absolute angular positions without re-calibration, while incremental encoders track rotational speed and direction via pulse counting to ensure trajectory stability.

Reliability Assurance in Harsh Environments

Compared to optical encoders, magnetic encoders resist dust, oil contamination, and moisture, preventing measurement distortion caused by environmental interference. Their non-contact nature also extends equipment lifespan and cuts maintenance frequency.

Encoders act as a robot's "motion fingerprint database"—unique magnetic field codes define action coordinates at distinct positions, with magnetic sensors serving as real-time "decoders" to translate mechanical motion into a digital control language.

Compact yet pivotal, this component bridges robot "mechanical motion" and "intelligent control", directly determining operational precision, environmental adaptability, and system reliability.

Solving your equipment sealing challenges

Contact us, and we shall promptly provide you with customized oil seal solutions through our expertise and capabilities.

Contact Us