Engine System

Product Application

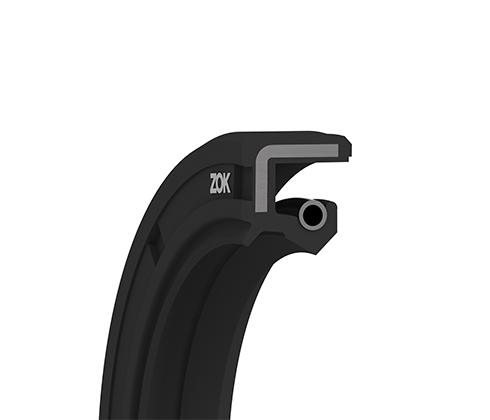

Material selection directly impacts service life: High-temperature conditions at the crankshaft necessitate fluorocarbon rubber (FKM) with heat resistance up to 200°C, while valve oil seals must also withstand fuel corrosion. Standard nitrile rubber (NBR) tends to harden and crack at elevated temperatures, increasing the risk of seal failure. During installation, pre-lubricate the lip and press-fit vertically to prevent lip tearing from uneven wear. Following periodic inspections for ageing cracks, replace with OEM-standard parts featuring metal reinforcement to ensure sealing reliability.

Failure consequences are severe: oil leakage not only pollutes the environment but also causes crankshaft bearings to seize due to lubrication loss. External dust ingress accelerates wear on precision components like camshafts, triggering engine noise or power reduction. Thus, though diminutive, engine oil seals serve as pivotal "gatekeepers" safeguarding lubrication system purity and pressure stability.

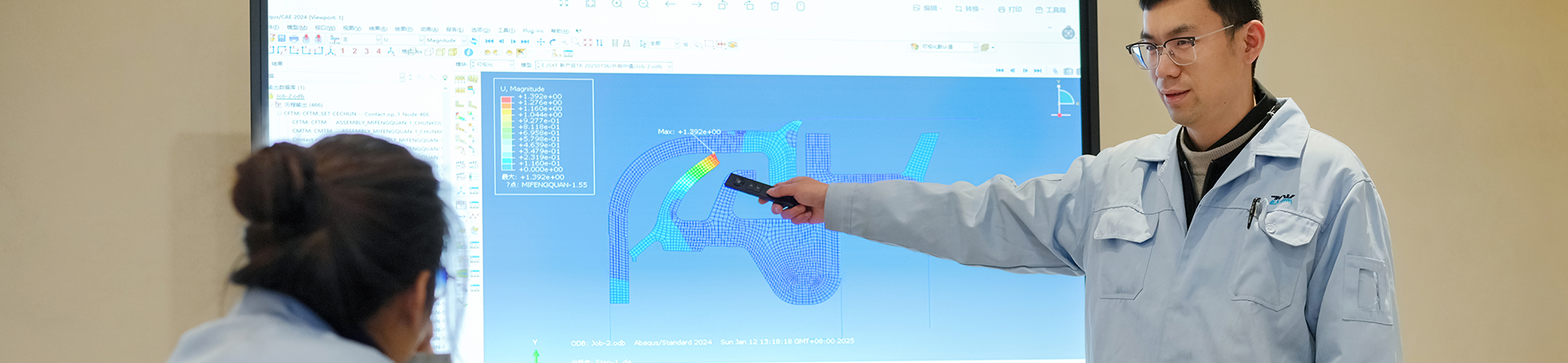

Solving your equipment sealing challenges

Contact us, and we shall promptly provide you with customized oil seal solutions through our expertise and capabilities.

Contact Us