Transmission System - Gearbox

Product Application

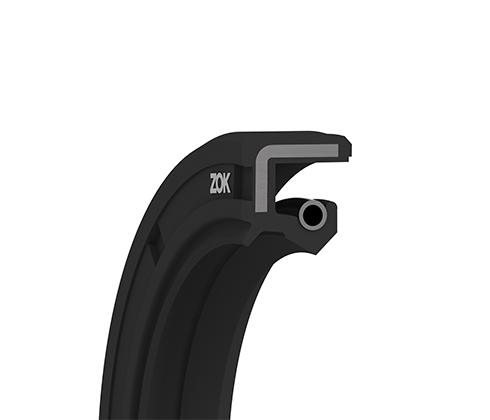

As the core sealing component within gearboxes, oil seals employ dynamic sealing technologies—such as double-lip structures and self-tightening springs—to establish dual protection at critical junctures including input/output shafts and half-shafts. This dual function prevents lubricant leakage, ensuring efficient operation of gears, bearings, and other components under stable oil film lubrication, while simultaneously barring ingress of external contaminants like dust and moisture to avert abnormal wear and corrosion. Material selection (e.g., oil-resistant NBR rubber, high-temperature FKM fluorocarbon rubber) and precision manufacturing (lip contact width 0.25mm ± tolerance) directly impact sealing efficacy. Failure may result in insufficient lubrication, abnormal oil pressure, or even systemic transmission malfunctions. Correct selection, standardised installation (e.g., controlling shaft surface cleanliness, preventing reverse assembly), and regular maintenance are crucial for ensuring the long-term stability of its "anti-leakage, anti-contamination, and pressure stabilisation" functions.

Solving your equipment sealing challenges

Contact us, and we shall promptly provide you with customized oil seal solutions through our expertise and capabilities.

Contact Us