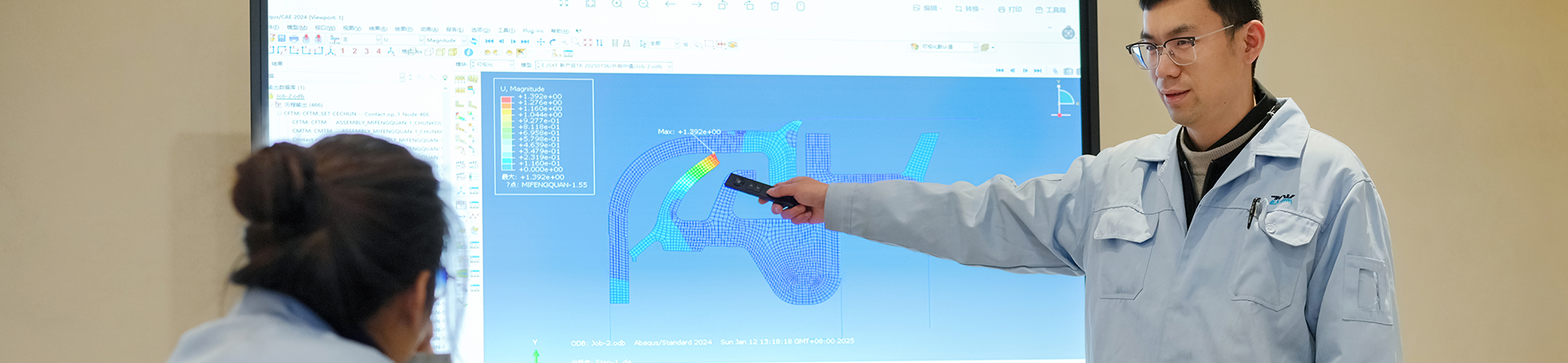

Innovative Research and Development

Research and Development Team Introduction

Elite R&D Team Configuration

We maintain a 40-strong specialised technical team covering all critical roles across the product development lifecycle, forming a comprehensive closed-loop system:

Core Role Configuration

1. Front-End Development Team

· Formulation Development Engineer: Focuses on material ratio innovation and performance optimisation

· Mould Development Engineer: Responsible for precision mould design and 3D printing validation

2. Central Support Team

· Product Development Engineer: Leading product functionality design and user experience optimisation

· Process Engineer: Specialising in production process refinement and mass production transition

3. Quality Assurance Team

· Test Engineer: Conducting environmental simulation and durability testing

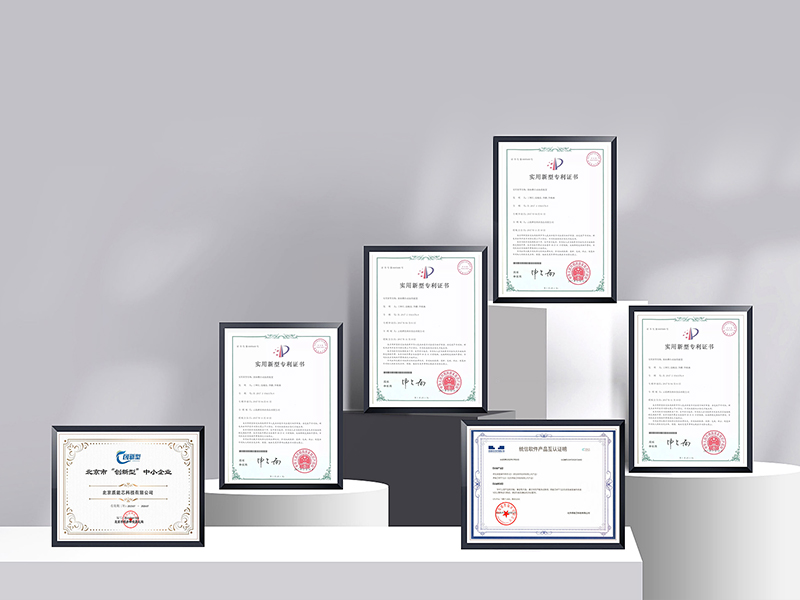

Patent

Patent

21 utility model patents;

Honours

Honours

High-efficiency production

Experience the allure of high-efficiency production

Digitalised Rigid Control

Data of each process and each piece of equipment is updated in real time to monitor product dynamics, product quality and equipment status. AGV trolleys deliver materials timely and accurately according to preset positions. QC inspectors and dedicated setup personnel scan the QR codes on product routing cards with handheld PDAs to retrieve the required process parameters within 3 seconds. Complete information of each process is fully recorded and managed with error-proofing measures. Paperless traceability is achieved via the MES system.

Human-Centred Soft Collaboration

During morning briefings, production team leaders allocate daily tasks within five minutes. The skills matrix indicates that 80% of this shift's personnel are multi-skilled operators. Electronic tags in the raw materials zone synchronise with WMS inventory, pushing alert notifications directly to supplier portals. The "Improvement Proposal Wall" in the break area displays last week's implemented jig optimisation plan, reducing per-unit operation time by 15 seconds. This culture of continuous improvement has enabled the factory to achieve 100% on-time delivery to customers for six consecutive months.

Full-process inspection

Full-process inspection

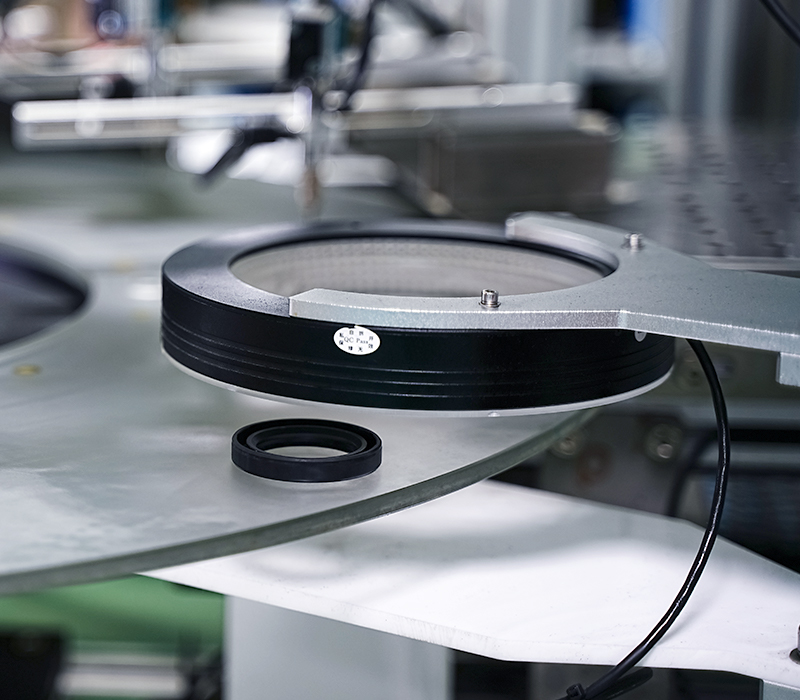

Raw Material Screening

We strictly control the source of raw material quality, conducting multi-level inspections ranging from supplier qualification verification to physical and chemical property testing. Hardness tests, physical experiments and other assessments are carried out to ensure that materials such as rubber and metal frameworks possess excellent oil resistance, elasticity and wear resistance, laying a solid foundation for the long-term stability of oil seals.

Dimensional inspection

Equipped with high-precision equipment such as coordinate measuring machines (CMMs) and laser diameter gauges, we conduct full-process monitoring of key dimensions of oil seals including outer diameter and lip thickness. Combined with an intelligent analysis system, real-time comparison against design drawings is performed to ensure that the product dimensional tolerance is controlled within ±0.05mm, meeting stringent assembly requirements.

Performance testing

We simulate actual operating conditions to conduct tests such as pressure sealing and high-speed durability, verifying the reliability of oil seals under harsh environments including extreme temperatures and chemical corrosion. Accelerated life tests such as salt spray testing and ozone aging testing ensure that the product service life reaches the industry-leading level.

On-time delivery

Rapid-response supply chain system

We have established a highly efficient and collaborative logistics team, partnering with leading service providers to achieve instant order processing through an intelligent logistics system. From meticulous warehouse management to optimised delivery routes, every step is executed with precision and efficiency, ensuring each of your goods is swiftly and accurately delivered via our logistics network.

After-sales support

Comprehensive after-sales support

7*24h customer service response

Instant solutions, ensuring your needs are met at all times.

24-hour output solutions

Solutions delivered within 24 hours to ensure your requirements are promptly addressed.

On-site technical support

Professional team, rapid response, providing on-site technical support.

Solving your equipment sealing challenges

Contact us, and we shall promptly provide you with customized oil seal solutions through our expertise and capabilities.

Contact Us